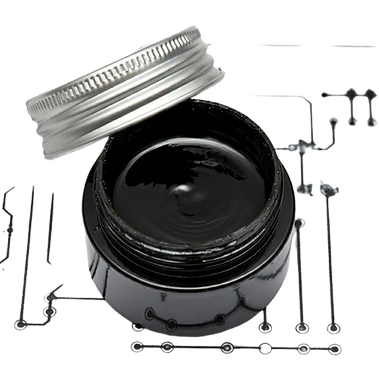

Conductive Paint – EMI Shielding & Electrical Conductivity Solutions

Conductive Paint for EMI Shielding, Grounding & Electronic Applications

Conductive Paint is a high-performance specialty coating designed to provide electrical conductivity, EMI/RFI shielding, grounding, and circuit repair on non-conductive and conductive surfaces. It contains conductive fillers such as silver, copper, nickel, or carbon, making it ideal for electronics, industrial enclosures, PCB repairs, and shielding applications.

Our conductive paint solutions are engineered for reliability, strong adhesion, and consistent electrical performance across multiple substrates.

What Is Conductive Paint?

Conductive Paint is a coating that converts ordinary surfaces into electrically conductive layers. It is widely used for:

-

EMI / RFI shielding

-

Electrical grounding

-

PCB trace repair

-

Electroplating preparation

-

Touch sensor creation

-

Static discharge control

Once applied and cured, the paint forms a continuous conductive path that helps reduce electromagnetic interference and improve electrical connectivity.

Key Features & Benefits

✔ High EMI / RFI Shielding Performance

Provides effective electromagnetic interference protection for plastic housings and electronic enclosures.

✔ Excellent Electrical Conductivity

Metal-filled options deliver strong conductivity for grounding paths and electronic repairs.

✔ Multiple Material Options

-

Silver Conductive Paint – Highest conductivity and premium EMI shielding

-

Copper Conductive Paint – Cost-effective with strong electrical performance

-

Nickel Conductive Paint – Corrosion-resistant with broadband shielding

-

Carbon Conductive Paint – Economical solution for low-frequency applications

✔ Easy Application

Can be applied by brush, spray, stencil, screen printing, or pen.

✔ Strong Adhesion

Bonds well to plastic, metal, glass, wood, paper, MDF, and fabric.

✔ ESD & Grounding Support

Creates discharge paths to reduce static buildup in electronic products.

Applications of Conductive Paint

EMI / RFI Shielding

Used to coat plastic enclosures and create Faraday-cage style protection for sensitive electronics.

Circuit Board Repair & Prototyping

Ideal for restoring broken PCB traces and building conductive patterns during development.

Electroplating Base Layer

Acts as a conductive primer on non-metal surfaces before electroplating.

Touch Sensors & Capacitive Interfaces

Used in interactive electronics, control panels, and smart devices.

Wearables & Educational Projects

Suitable for e-textiles, DIY electronics, and learning environments.

Technical Specifications

-

Conductivity: Depends on filler type (Silver highest → Carbon lowest)

-

Shielding Effectiveness: Suitable for low to high frequency EMI

-

Drying: Fast air-dry curing

-

Application Methods: Brush, spray, stencil, screen print

-

Surface Compatibility: Plastic, metal, glass, wood, fabric

Why Choose Our Conductive Paint?

-

Reliable electrical continuity

-

Industrial-grade EMI shielding

-

Multiple conductivity levels available

-

Easy application on complex surfaces

-

Suitable for electronics, manufacturing, and R&D

-

Technical support available for custom requirements

We provide professional conductive coating solutions tailored to your application needs.

Contact Us

For pricing, datasheets, or technical support:

📞 +91 8901711018

📧 info@safecableconnect.com