Why Polyolefin Heat Shrink Sleeves need to use in Heat Shrink Joint Kit and Heat Shrink Termination Kit?

- Ms Powertech

- Jul 2, 2025

- 5 min read

Updated: Jul 31, 2025

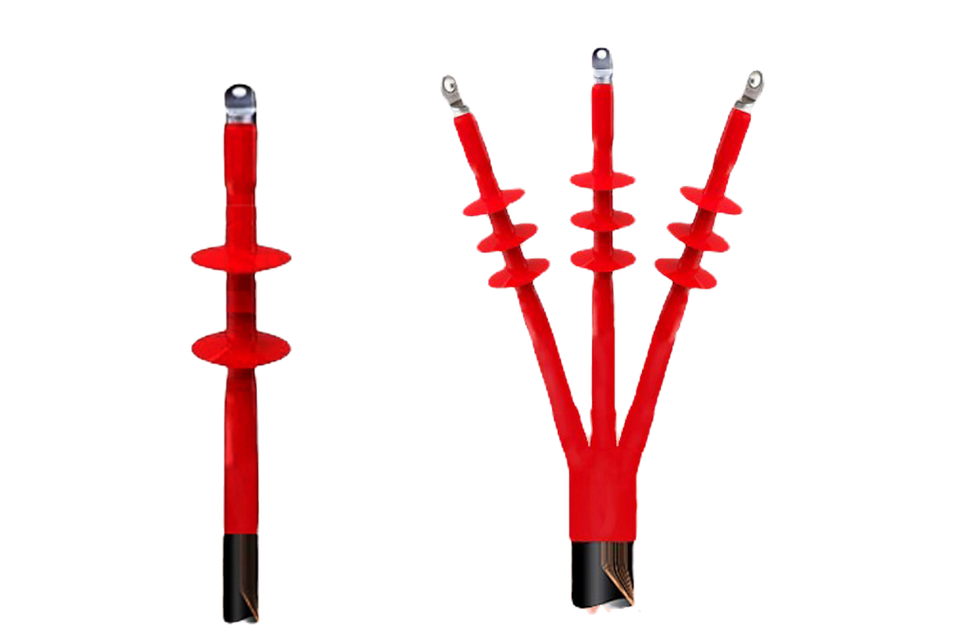

Polyolefin (cross‑linked polyethylene) Heat‑Shrink sleeves are a core component of cable joint and termination kits—especially for medium- to high-voltage power cables—because they deliver a robust, long-lasting, and easy-to-install solution. Here’s why they’re used:

1. Excellent Electrical Insulation

Polyolefin offers high dielectric strength, providing reliable insulation across cable joints and terminations, helping prevent short circuits.

2. Superior Thermal Performance

It handles a wide temperature range (typically –55 °C to +125 °C, up to +135 °C variants).

The shrink process starts around 100–125 °C, and the material recovers quickly—ideal for field installations.

3. Strong Mechanical & Environmental Protection

Provides abrasion resistance, strain relief, and toughness—protecting joints from flex, tension, and external damage .

Chemical, solvent, UV resistance ensures durable outdoor use, even against pollutants or salt fog.

Flame-retardant properties reduce fire risk .

4. Effective Environmental Sealing

Heat Shrink (adhesive-lined) polyolefin sleeves melt their inner adhesive layer during shrinkage, filling gaps and creating hermetic seals against moisture and contaminants.

5. Flexible Sizing Options

Available in 2:1, 3:1, and even 4:1 shrink ratios, polyolefin tubes can snugly conform to irregular shapes, joints, or connectors.

6. Ease of Installation & Reliability

Lightweight, fast-shrinking, and flexible—ideal for use with a heat gun, with rapid field installation possible.

Adhesive-lined versions seal while shrinking, saving time and effort.

7. Cross‑linked Strength

·Cross-linking transforms polyolefin into a semi-rigid/zoned memory material that recovers to precise shape when heated, retaining this shape through thermal cycles.

Why you may choose “SAFE CONNECT”

SAFE CONNECT is an ISO-certified company that offers a wide range of Cable Joint Kits and Termination Kits, compliance with IS 13573, IEC 60502, CENELEC, and IEEE 48 standards. Our Heat Shrinkable Sleeves and components are manufactured in accordance with ENA 09-13 and ASTM standards. We utilize Cross-linked Polyolefin Heat Shrinkable Sleeves and components in our Heat Shrink Joint Kits and Termination Kits, providing robust, long-lasting, and easy-to-install solutions. Our core strength in our In-House Production Facility, Laboratory, and Quality & R&D Team, all focused on delivering high-quality standard products. We offer our customers 24/7 solutions worldwide. Our Product Range includes:

1.1kV to 3.3kV L.T. (L.V) Heat Shrink Straight Through Joint Kit for Control Cable

1.1kV to 3.3kV L.T. (L.V) Heat Shrink Termination Kit for Control Cable

6.6kV (11kV) 12kV (M.V) Heat Shrink Indoor Termination Kit for 1, 3, 4 Core control cable

6.6kV (11kV) 12kV (M.V) Heat Shrink Outdoor Termination Kit for 1, 3, 4 Core control cable

6.6kV (11kV) 12kV (M.V) Heat Shrink Straight through joint Kit for 1, 3, 4 Core control cable

Comments